Home Improvement

Toilet Articles

|

A toilet is an essential component of every household plumbing system. Although

toilets are generally sturdy and dependable, most homeowners or apartment residents

will experience some kind of issue with their toilet. Clogging is the most common

problem, but there are other concerns as well. For instance, the tank can make

strange noises, or water may run constantly. Fortunately, most toilet problems

can be rectified by a DIY plumber.

If you enjoy doing things yourself, knowing how to fix common problems with your

toilet can help you avoid calling a professional. This article will cover various

topics related to toilet repair.

How to Replace a Toilet Seat

Replacing the toilet lid and seat is the simplest repair task. There are numerous

styles of replacement seats available, making it easy to find one that matches

your bathroom color scheme or decor. Most modern toilets are produced in two

standard sizes, and seats are manufactured to fit them.

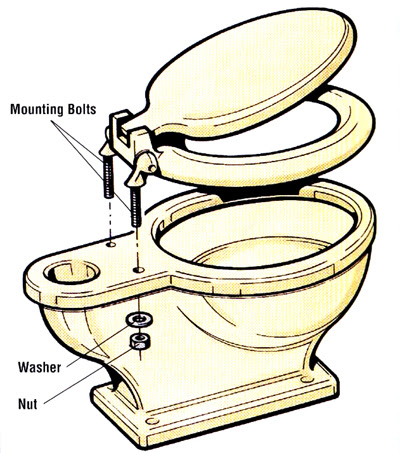

Once you have purchased the appropriate size seat, remove the old one. Take off

the two nuts on the hinge and lift the old toilet seat up and out. One common

issue is that the nuts holding the toilet seat may be corroded or rusted. In

some cases, the nuts on toilet seats are recessed and difficult to reach, making

the job even more challenging.

To install a new toilet seat, insert the two bolts, slide on the washers,

and tighten the nuts. Be cautious not to overtighten the nuts or removing the

seat could be difficult later.

If you can access the fasteners easily, a penetrating oil can be applied to help

loosen them. Give the oil sufficient time to soak in. Use a wrench or, if the

nuts are not within reach of a regular wrench, a deep socket wrench. Do not exert

too much force; if the wrench slips off a stubborn nut, it may hit and damage

the tank or bowl.

Sink, Tub and Drain Troubleshooting Guide

Problem |

Possible Cause |

Solution |

| Water in tank runs constantly | Float ball or rod is misaligned. | Bend float rod carefully to move ball so it will not rub against side of tank. |

| Float ball contains water. | Empty or replace float ball. | |

| Float ball not rising high enough. | Carefully bend float rod down, but only slightly. | |

| Tank ball not sealing properly at bottom of tank. | Remove any corrosion from lip of valve seat. Replace tank ball if worn. Adjust lift wire and guide. |

|

| Ballcock valve does not shut off water. | Replace washers in ballcock assembly or, if necessary, replace entire assembly. |

|

|

Toilet does not flush or flushes inadequately |

Drain is clogged. | Remove blockage in drain. |

| Not enough water in tank. | Raise water in tank by bending float rod up slightly. | |

| Tank ball falls back before enough water leaves tank. | Move guide up so tank ball can rise higher. | |

| Leak where tank joins toilet bowl. | Tighten nuts on spud pipe; replace spud washers, if necessary. | |

| Ports around bowl rim clogged. | Ream out residue from ports. | |

| Tank whines while filling | Ballcock valve not operating properly. | Replace washers or install new ballcock assembly |

| Waster supply is restricted. | Check shutoff to make sure it’s completely open. Check for scale or corrosion at entry into tank on valve. |

|

| Moisture around fixture | Condensation. | Install foam liner, tank cover, drip catcher or temperature valve. |

| Leak at flange wax seal. | Remove toilet and install new wax ring seal. | |

| Leak at bowl-tank connection. | Tighten spud pipe nuts; replace worn spud washers, if necessary. | |

| Leak at water inlet connection. | Tighten locknut and coupling nut; replace washers and gasket, if necessary. |

|

| Crack in bowl or tank. | Replace bowl, tank, or entire fixture. |

If all else fails, you may need to use a hacksaw to cut off the bolts. To

protect the bowl’s finish, apply tape to the bowl where the hacksaw

blade may rub against it. Then insert the blade under the hinge and saw

through the bolts. Be extremely careful when using the saw, as a careless slip

with a hacksaw can crack the fixture just as easily as a blow with a wrench.

With the nuts removed or the bolts cut, you can remove the old seat without

further difficulty. Clean the area before installing the new seat. To install

the new seat, insert the bolts and tighten the nuts carefully, making sure

not to overtighten them, as you may need to replace this seat in the future.

If you live in a rented apartment and install a new seat that you paid

for yourself, be sure to keep the old one. When you’re ready to leave,

you can replace the new one with the original and take the new seat with you.

If the rubber bumpers on the bottom of your toilet lid and seat are worn out, you can purchase replacements at a hardware store. Some bumpers screw in, while others require nailing or gluing. When installing new ones, try to cover the original holes as much as possible.

To unclog a toilet, use a plunger to create suction. Make sure there’s enough water in the bowl to cover the suction cup, and pump the plunger up and down. If there’s not enough water, add some from another source. If the plunger doesn’t work, try using a wire coat hanger or a closet or toilet auger. The auger has a long tube to guide the hook into the trap, and a crank to turn it. If all else fails, you may need to remove the toilet from the floor to access the blockage.

If your toilet tank is making strange noises or running continuously, it could be wasting water and money. However, most tank problems are easy to fix.

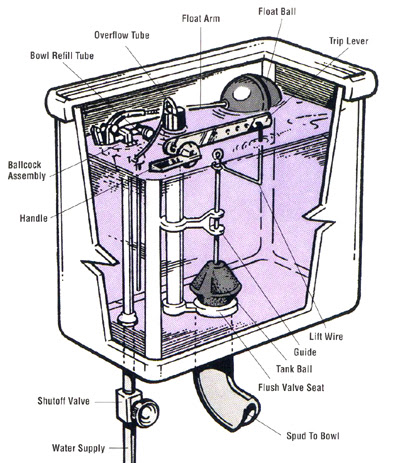

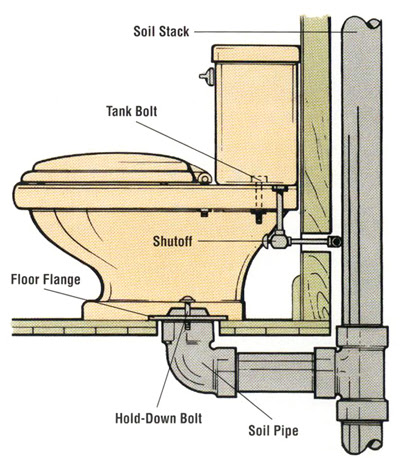

Toilet tank issues are a common and frustrating problem that could lead to

wastage of water and money. Fortunately, most of these problems can be resolved

easily and quickly. The image below shows a typical toilet tank and its components.

Once you understand the functioning of a toilet, you can start identifying the

source of the issues in the tank. Remove the lid of the toilet tank and follow

these steps to identify the problem.

When you push the handle on the tank to flush the toilet, a trip lever is raised

inside the tank. This lever lifts wires that lift the tank ball or rubber flap

at the bottom of the tank. The water in the tank flows out into the bowl through

the flush valve opening once it is clear of any obstruction by the raised tank

ball. This causes the water level in the bowl to rise above the level of water

in the toilet trap.

While the water is flowing out of the tank, the float ball, which is floating

on top of the water in the tank, drops down. This pulls down on the float arm,

raising the valve plunger in the ballcock assembly and allowing fresh water

to flow into the tank. The water from the tank pushes the bowl water out into

the drain and causes a siphoning action that cleans everything out of the bowl.

The siphoning stops when all the water is gone from the toilet bowl and air is

drawn into the trap. The tank ball falls back into place, closing the flush valve

opening.

As the water level in the tank rises, the float ball also rises until the float

arm is high enough to lower the valve plunger in the ballcock assembly and shut

off the incoming water. If the water does not shut off, the excess water flows

down into the bowl through an overflow tube to prevent the tank from overflowing.

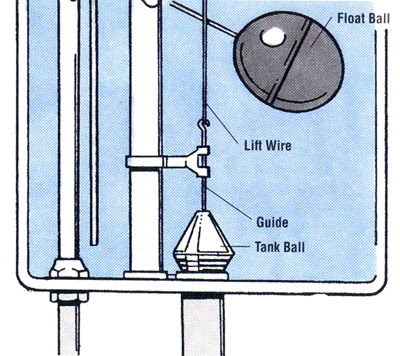

If water flows continuously out of the tank to the bowl and down the drain:

Step 1: Pull up on the float arm. If the water stops, then the problem is that

the float ball doesn’t rise far enough to lower the valve plunger in the ballcock

assembly. One reason could be that the float ball is rubbing against the side of

the tank. If so, bend the float arm slightly to move the ball away from the tank

side.

If your toilet is running continuously, check the guide and lift wire that

raises and lowers the tank ball to make sure they are aligned properly.

Step 2: If the ball doesn’t touch the tank, continue to hold the float arm and

remove the ball from the end of the arm by turning it counterclockwise. Shake the

ball to see if there’s any water inside it, as the weight of the water inside could

prevent the ball from rising normally. If there is water in the ball, shake it out

and put the ball back on the float arm. If the ball is damaged or corroded, replace

it with a new one. If there’s no water in the ball, put the ball back on and gently

bend the float rod down to lower the level the float ball must reach to shut off

the flow of fresh water into the tank.

To fix a toilet that continues to run, there are a few steps to follow. First, check the float ball to make sure it is not obstructed or damaged. If it is, adjust or replace it as necessary. If that does not solve the problem, move on to the tank ball at the flush valve seat. Chemical residue or decay may prevent it from seating properly, and wet-dry emery cloth or steel wool can be used to clean away any debris. If excess water still flows through the toilet, the guide or lift wire may be out of line or bent. Make sure they are correctly positioned, and if necessary, bend a wire back to the correct position or install a new one. If neither the float ball nor the tank ball is at fault, then the issue must be with the ballcock assembly. To fix this, turn off the water shutoff valve, remove the valve plunger, replace any faulty washers or O-rings, and replace the ballcock assembly if necessary. When purchasing a replacement assembly, ensure it has a threaded shank the same size as the old one. Plastic units are available and less expensive, but metal ones are sturdier and more durable.

To replace a ballcock assembly in a toilet, start by locating the coupling or slip nut under the tank where the water inlet pipe enters the base of the tank. Loosen the coupling nut and use an adjustable wrench to grip the retaining or locknut immediately above the slip nut under the tank. Use another wrench to grip the base of the ballcock assembly shaft inside the tank. Unscrew the locknut under the tank to remove the old assembly. If the nut is stubborn, use penetrating oil to loosen it. Lift the old assembly out of the tank, saving the washers from all connections. New ones will probably be included with the replacement unit, but keep the old parts until you’ve installed the new ballcock assembly in case new parts are damaged during installation.

When installing a new ballcock assembly, ensure that the gasket and washer are properly seated and firmly secured by the retaining unit. Insert the new ballcock assembly into the hole in the tank and tighten the locknut on the outside sufficiently to make the inside washer fit watertight against the hole, but don’t over-tighten it. Replace the coupling nut and water inlet pipe, reinstall the float arm, and set the refill tube into the overflow tube. Turn the water back on at the toilet shutoff valve and check for leaks at all points. Make sure the float ball does not rub against the back of the tank.

Newer types of ballcock assemblies eliminate the float arm and the float ball. One type features a plastic cup that floats up to cut off the water as the tank fills. You can set the water level in the tank by adjusting the position of the plastic cup on a pull rod. Another type is a small unit that rests almost on the bottom of the tank; it’s diaphragm-powered valve senses the level of the water from down there. Since it requires no tools, this assembly is easy to install. To install these newer ballcock assemblies, turn off the tank’s water supply shutoff valve, flush the toilet to drain the tank, and remove the old ballcock assembly. Slip the parts over the water inlet pipe under the tank in this order: coupling nut, friction washer, cone washer, and retaining or mounting nut.

Step 3: Put the new unit into the toilet tank, making sure to fit the threaded shank through the hole over the water supply pipe and ensuring that the gasket fits into the hole. Hand-tighten the retaining or mounting nut under the tank onto the threaded shank. Push the washers into place and hand-tighten the coupling nut under the tank, being careful not to over-tighten it.

Step 4: Attach one end of the refill tube to the tank’s overflow pipe inside the tank and place the other end on the stem of the replacement unit.

Step 5: Open the water supply valve to fill the tank. The water level in the tank can be adjusted by a knob on the new valve unit.

Solving Common Toilet Problems

What can you do if there is not enough water coming from the tank to flush the toilet bowl clean?

Step 1: Check the water level in the tank. If the water level is too low and does not reach within 1 ½ inches of the top of the overflow tube, bend the float arm up slightly to allow more water to enter the tank.

Step 2: If the water level is correct but there is still not enough water to clean the bowl properly, the problem may be with the tank ball on the flush valve seat at the bottom of the tank. The ball is probably dropping too soon because the guide is set too low. Raise the guide, but make sure it stays in line with the lift wire. If the guide and wire are out of alignment, the tank ball will not drop straight into the valve seat opening, and the toilet will run continuously.

Step 3: Check for other causes of inadequate flushing. The small ports around the underside of the toilet bowl’s rim may become clogged with residue from chemicals in the water and prevent a sufficient amount of tank water from running out into the bowl. You can use a small mirror to examine the holes, and a piece of wire coat hanger or an offset Phillips screwdriver to remove any clogged debris.

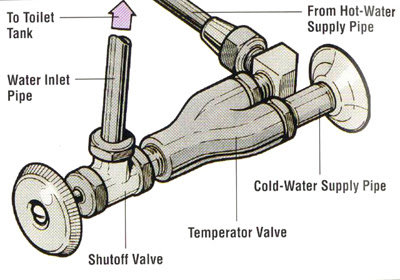

Another common problem among toilets is sweating and dripping onto your floors. There are jackets that are designed specifically to fit over the tank and absorb the moisture. There are also drip pans that fit under the tank to catch the dripping condensation so that it does not damage your bathroom floor. A device called a temperator valve is another way to combat tank sweating. This valve provides a regulated mixture of hot and cold water, which lessens the difference between the temperature inside the tank and the temperature of the surrounding air. It is this difference in temperature that causes condensation, or sweating. Consider installing a temperator valve if the water in the tank is usually below 50 degrees Fahrenheit.

To prevent toilet tank sweating, a temperator valve can be installed which needs hot and cold water supply connections.

The installation of a temperator valve requires hot water to be connected to the valve which may not be feasible if there is no hot water line close to the toilet. Furthermore, even with a temperator valve, condensation can still occur if the water inside the tank cools between flushes. If a leak is detected, it may be due to loose connections, defective washers on the spud pipe or where the water inlet pipe and ballcock assembly are attached to the tank. In such cases, worn gaskets or washers should be replaced and all nuts tightened. The repaired connection can be tested with bluing in the water.

If water is seeping out from under the toilet bowl, the wax ring seal that joins the bowl to the drain outlet may be defective. The bowl needs to be removed, and a new gasket installed. If the leak is due to a crack in the tank or bowl, the entire toilet must be replaced.

Replacing a Toilet

Removing and replacing a toilet should only be done when necessary. If the toilet is clogged beyond repair, or if it leaks around its base, or if it is old and needs replacing, then removing and reinstalling the old toilet or installing a new fixture is the solution.

It is important to note that local plumbing code may prohibit anyone but a licensed plumber from doing the job. Check the code for your community to make sure it is okay for you to undertake the task. To replace a toilet:

Step 1: Measure the rough-in distance, which is the distance from the wall behind the bowl to the center of the toilet floor drain. Measure from the wall to the center of either of the two hold-down bolts, one on each side of the toilet, that hold the fixture to the floor. If there are two bolts on each side, measure to the center of the rear bolt.

Step 2: Choose a replacement toilet unit that fits properly in your bathroom based on the rough-in distance. You can replace your old toilet with a more modern fixture, but you must make sure that the new unit will fit into the space between the drainpipe and the wall. You can install a smaller unit, but you cannot put a larger toilet into a space that was occupied by a smaller fixture.

Step 3: Shut off the water supply to the toilet tank, then remove all the water from both the tank and the bowl. Trip the flush handle to eliminate most of the water from the tank. Then soak up whatever water is left with a sponge. Bail out the water in the bowl with a small container, and then use a sponge to dry out the bowl completely.

Step 4: If the tank is connected to the wall, remove the hanger bolts inside the tank that secure the tank to the wall. Then remove the pair of bolts at the bottom of the tank that connect the tank to the bowl. Remove the tank and set it out of the way.

Step 5: If there are any, remove the caps covering the hold-down bolts at the base of the bowl. Most of these caps are made of ceramic to match the bowl, but some are attached with plumbers’ join compound and can be pried off with a putty knife, while others are threaded and can be unscrewed. Before proceeding, brush away any dried compound after removing the caps.

Step 6: Remove the hold-down nuts or bolts. These may be difficult to remove, but applying some penetrating oil should make it easier. If you plan to reinstall the bowl, keep the washers and bolts. Once the hold-down nuts or bolts are removed, there is nothing else holding the bowl to the floor. Caution: To prevent sewer gas from backing up the drain, you should plug the opening while you work. Tie a cord around an old towel so it won’t fall through the opening and jam this plug into the drain.

Step 7: Remove the bowl. Because the bowl and the tank can crack from just one sharp blow to the porcelain, lay out an old piece of carpeting on which you can lay the fixtures. You should also have a bucket and sponge handy to soak up the water you couldn’t bail out earlier. With your work surface prepared, gently rock the bowl back and forth to loosen it, and then lift it straight up. It weighs about 60 or 70 pounds. Set the bowl on the piece of carpeting.

Step 8: Inspect the uncovered drain. If necessary, clear the drain. Once the pipe is clear, you can proceed with the replacement of the toilet.

Step 9: Installing a new toilet and reinstalling the old one are done in the same way. Scrape away all the old putty or other sealing material from both the bottom of the bowl and the floor flange with a putty knife.

Typical installing of a two-piece floor-mounted toilet.

The rough-in distance can be measured with the toilet in place by measuring

from the wall to the center of the hold-down bolt, or to the center of the rear

bolt if the fixture is held by two pairs of bolts.

Inspect the floor where the toilet was. If the floor has rotted, it will need to be rebuilt before the toilet can be installed. Depending on the extent of the damage, the rebuilding may involve the floor, the subfloor, and even the joists. In that case, have a carpenter rebuild the damaged area before installing the toilet. Also, inspect the flange and bolts that come up from the flange. If the flange is damaged or the bolts are stripped, replace the faulty part or parts before proceeding.

Step 10: Put a new sealer ring on the water outlet opening on the bottom of the new bowl. With the fixture upside down, place the sealer ring on the bottom of the bowl. If the floor flange is recessed, you will need a gasket with a plastic sleeve in the ring. This sleeve should face towards you as you position it since it will go into the soil pipe.

Step 11: Apply a uniform layer of the toilet-bowl setting compound, about 2 1/8 inches thick, around the edge of the bowl at the base. This compound is available at hardware and plumbing-supply stores.

To install a toilet, first remove the plug from the drain or soil pipe. Turn the bowl right side up and place it over the flange, guiding the bolts into place. Press down firmly, and give the bowl a slight twist to ensure the wax ring seats properly against the flange. Place a level across the bowl to check if it is level, and adjust it as necessary without disturbing or breaking the seal of the wax ring. Next, hand-tighten the nuts to hold the bowl to the floor, but do not over-tighten them, or the fixture may crack. Coat the hold-down nuts and bolts with toilet bowl setting compound and reinstall the caps. If the tank and bowl are separate fixtures, attach the tank by rebolting a wall-mounted tank or reinstalling the bolts and washers connecting a bowl-supported tank. Replace any damaged parts. If the tank and bowl are connected with a spud pipe, apply pipe joint compound to the threads of the spud slip nuts and tighten them in place. Finally, reconnect the water supply inlet pipe to the tank, ensure the ballcock assembly is correctly attached, and turn the water back on. For more information, check out related articles on HowStuffWorks, including How Toilets Work, How Tankless Toilets Work, How Low-flow Toilets Work, How Dual Flush Toilets Work, How to Repair a Dishwasher, How to Repair a Dryer, How to Repair Major Appliances, and Top 10 Appliances We Can’t Live Without.

FAQ

1. What are some common toilet problems that can be repaired?

There are several common toilet problems that can be repaired, such as a running toilet, a clogged toilet, a leaking toilet, or a weak flushing toilet. A running toilet occurs when water continues to flow into the toilet bowl after it has been flushed. A clogged toilet happens when there is an obstruction in the drain pipe that prevents water and waste from flowing out of the bowl. A leaking toilet can cause water damage to the floor and is often caused by a faulty wax ring or loose bolts. A weak flushing toilet may be caused by a clogged rim or bowl jet holes, or a malfunctioning flapper valve.

2. How can I fix a running toilet?

To fix a running toilet, first, check the flapper valve at the bottom of the tank to see if it is damaged or worn out. If so, replace it with a new one. If the flapper valve is in good condition, check the chain that connects it to the flush lever to make sure it is not too loose or too tight. Adjust it if necessary. If neither of these solutions works, the problem may be with the float or fill valve. Adjust the float to ensure that the tank fills to the proper level, or replace the fill valve if it is faulty.

3. How do I unclog a toilet?

To unclog a toilet, start by using a plunger to create suction and force the obstruction through the drain pipe. If the plunger does not work, try using a plumbing snake to break up the blockage. If neither of these methods works, you may need to remove the toilet from the floor to access the drain pipe and remove the obstruction manually. Use caution when attempting this, as it can be messy and difficult.

4. What should I do if my toilet is leaking?

If your toilet is leaking, the first step is to locate the source of the leak. Check the wax ring and bolts that secure the toilet to the floor to see if they are loose or damaged. Tighten or replace them if necessary. If the leak is coming from the tank, check the bolts that attach the tank to the bowl to make sure they are tight. If they are, the problem may be with the tank gasket or the flush valve. Replace these components if needed.

5. How can I improve my toilet’s flushing power?

To improve your toilet’s flushing power, first, make sure the water level in the tank is set to the proper level. If it is too low, the toilet may not flush properly. Next, check the rim and bowl jet holes to see if they are clogged with mineral deposits or other debris. Clean them out with a wire hanger or a specialized toilet brush. Finally, make sure the flapper valve is sealing properly. If it is not, replace it with a new one.

Brody is a skilled craftsman and gardening expert. From renovating living spaces to cultivating lush gardens, Brody’s knowledge and passion shine through, inspiring readers to embark on their own home improvement and gardening journeys with confidence.

Leave a Reply