Home Improvement

Toilet Articles

|

A toilet is an essential fixture in any home. Although toilets are built to last, it’s not uncommon for homeowners or renters to encounter problems with them. The most common issue is clogging, but there are other problems as well. The tank can make strange noises, or water can run continuously. Fortunately, most toilet problems can be fixed by a do-it-yourself plumber.

If you consider yourself a handy person, learning some quick fixes can save you a call to the plumber. In this article, we’ll discuss various toilet issues and how to fix them.

How to Replace a Toilet Seat

Replacing the toilet lid and seat is the easiest repair task. With so many styles of replacement seats available, finding one that matches your bathroom color scheme or motif is a breeze. Most modern toilets come in two standard sizes, and replacement seats are made to fit them.

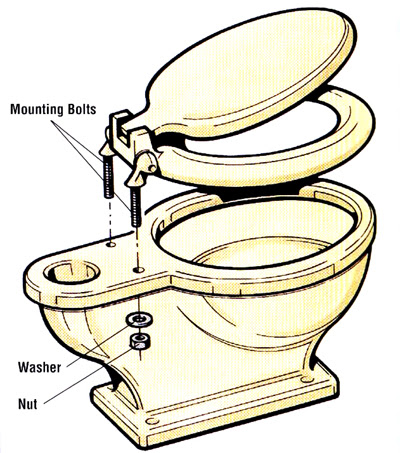

Once you have the right size seat, remove the old one. Remove the two nuts on the hinge and lift your old toilet seat up and out. A common problem is that the nuts securing the toilet seat may be rusted or corroded. The nuts on some toilet seats are recessed and practically inaccessible, making the job even more difficult.

To install a new toilet seat, insert the two bolts, slip on the washers, and tighten the nuts. Be careful not to over-tighten the nuts, or the seat might be hard to remove later.

If you have trouble accessing the fasteners, use penetrating oil to help loosen them. Apply the oil and give it plenty of time to soak in. Use a wrench or a deep socket wrench if you can’t reach the nuts with a regular wrench. Be careful not to use too much force, or the wrench might slip, causing damage to the tank, bowl, or anything else in the vicinity.

The Sink, Tub, and Drain Troubleshooting Guide provides solutions to common problems. A table with three columns labeled “Problem,” “Possible Cause,” and “Solution” lists issues such as constant water flow, clogged drains, and leaks. The guide suggests solutions such as adjusting the float ball, clearing blockages, and tightening nuts or replacing worn parts. In extreme cases, the entire fixture may need to be replaced. If removing a seat, apply tape to protect the bowl and use a hacksaw with caution to prevent damage. Finally, be careful not to over-tighten nuts and keep the original seat if living in a rental property.

If the rubber bumpers on the bottom of your toilet lid and seat are worn out, you can replace them with new ones. You can buy these bumpers at a hardware store and install them in the original holes to conceal them. Some bumpers need to be nailed or glued while others can be screwed in.

To clear a clogged toilet, you can use a plunger. Ensure that there is enough water in the bowl to cover the suction cup of the plunger. If there is not enough water, do not flush the toilet as it will overflow. Instead, add water from another source. Use a plunger with a bulb-type head, which is effective for unclogging toilets. If plunging doesn’t work, you can try using a wire coat hanger or a closet or toilet auger to remove the blockage.

Tank problems, such as strange noises or continuous water running, can be easily solved to prevent water wastage.

Troubles with toilet tanks are a common and frustrating problem that may cause you to waste water and money. Nevertheless, most issues can be dealt with quickly and easily. The picture shows a typical toilet tank and its components. Once you understand how the toilet works, you can start looking for the source of the problem. Simply remove the lid of the toilet tank to follow the process.

When you flush the toilet by tripping the handle, a trip lever inside the tank is raised. This lever lifts wires, which then raise the tank ball or rubber flap at the bottom of the tank. When the flush valve opening is clear, the water in the tank rushes out past the raised tank ball and into the toilet bowl below. This raises the level of water in the bowl above the level of water in the toilet trap.

While the water is flowing out of the tank, the float ball, which floats on top of the water in the tank, drops down. This pulls down the float arm and raises the valve plunger in the ballcock assembly, allowing fresh water to flow into the tank. Since water seeks its own level, the water from the tank pushes the bowl water out into the drain, causing a siphoning action that cleans everything out of the bowl. When all the water is gone from the toilet bowl and air is drawn into the trap, the siphoning stops. Meanwhile, the tank ball falls back into place, closing the flush valve opening.

As the water level rises in the tank, the float ball rises until the float arm is high enough to lower the valve plunger in the ballcock assembly and stop the incoming water. If the water fails to stop, there is an overflow tube that carries excess water down into the bowl to prevent the tank from overflowing. If water flows continuously out of the tank into the bowl and down the drain:

Step 1: Lift the float arm. If the water stops, it means that the float ball doesn’t rise far enough to lower the valve plunger in the ballcock assembly. One reason for this could be that the float ball is rubbing against the side of the tank. If this is the case, bend the float arm slightly to move the ball away from the tank side.

If your toilet runs continuously, check the guide and lift wire that raises and lowers the tank ball to make sure they are aligned properly.

Step 2: If the ball doesn’t touch the tank, continue to hold the float arm and remove the ball from the end of the arm by turning it counterclockwise. Then shake the ball to see if there’s water inside it, as the weight of the water inside could be preventing the ball from rising normally. If there is water in the ball, shake it out and put the ball back on the float arm. If the ball is damaged or corroded, replace it with a new one. If there is no water in the ball, put the ball back on and gently bend the float rod down to lower the level the float ball must reach to shut off the flow of fresh water into the tank.

Step 3: If the previous steps do not solve the issue, inspect the tank ball located at the flush valve seat. Sometimes, chemical residue from the water prevents the ball from seating correctly, or the ball may have decayed. This results in water seeping through the flush valve opening into the toilet bowl below. To fix this problem, turn off the water at the toilet shutoff valve and flush the toilet to empty the tank. Then, check the tank ball for signs of wear and replace it if necessary. If the issue is chemical residue on the lip of the flush valve opening, use wet-dry emery cloth, steel wool, or a knife to clean away the debris.

Step 4: If excess water still flows through the toilet, the guide or lift wire that raises and lowers the tank ball may be out of line or bent. Ensure that the guide is in place and the wire is directly above the flush valve opening. Rotate the guide until the tank ball falls straight down into the opening. If the lift wire is bent, try bending it back to the correct position or replace it. Make sure that the trip lever rod is not rubbing against anything and the lift wire is not in the wrong hole of the rod. Either of these situations could cause the tank ball to fall at an angle and not block the opening.

If neither the float ball nor the tank ball is at fault, then the issue must be in the ballcock assembly.

Fixing a Toilet Ballcock Assembly

The ballcock assembly may look complicated, but it’s not. At a hardware or plumbing-supply store, you can buy a new ballcock assembly. Both plastic and metal units are available. Plastic costs less and will not corrode, but metal ones are sturdier. Additionally, plastic units cannot be repaired since many of them are sealed. However, you can buy a different type of unit as long as the new assembly has a threaded shank the same size as the old one. If possible, bring the old assembly with you when you buy the replacement. Here’s how to fix an older-style ballcock assembly:

Step 1: Ensure that the water shutoff valve for the toilet is in the OFF position.

Step 2: Remove the valve plunger, and you’ll see one or two washers or O-rings. If any of these parts are faulty, water will flow out past the plunger continuously, and the toilet will run constantly. Inspect all washers and replace any defective ones.

Step 3: If the ballcock assembly is sealed, replace it as a unit. Shut off the toilet water supply at the shutoff valve and flush the tank. Unscrew the float arm from the old ballcock unit and remove the refill tube from the overflow tube.

Step 4: Check if there is a coupling or slip nut under the tank where the water inlet pipe enters the base of the tank. Loosen the coupling nut to free the water inlet pipe. Use an adjustable wrench to grip the retaining nut or locknut above the slip nut and another wrench to grip the base of the ballcock assembly shaft inside the tank.

Step 5: Use penetrating oil to loosen the locknut under the tank if it is stubborn. Unscrew the locknut to remove the ballcock assembly.

Step 6: Save the washers from all connections, inside and outside the tank, while lifting the old assembly out of the tank. Keep the old parts until you install the new ballcock assembly in case the new parts are damaged during installation. The replacement unit will probably include new ones.

Step 7: Insert the new ballcock assembly into the hole in the tank with the inside washer in place. Tighten the locknut on the outside until the inside washer fits watertight against the hole. Do not over-tighten it.

Step 8: Reinstall the float arm, set the refill tube into the overflow tube, and replace the coupling nut and water inlet pipe.

Step 9: Check for leaks at all points and ensure that the float ball does not rub against the back of the tank after turning on the water at the toilet shutoff valve.

Newer types of ballcock assemblies eliminate the float arm and float ball. One type features a plastic cup that floats up and cuts off the water as the tank fills, allowing the water to run full-force until the tank is filled. It shuts the water off immediately, eliminating groaning noises that some toilets make as a float arm gradually closes the valve. You can set the water level by adjusting the position of the plastic cup on the pull rod. Another type of ballcock assembly is a small unit that rests almost on the bottom of the tank and uses a diaphragm-powered valve to sense the water level. This assembly is an easy unit to install since it requires no tools.

To install these newer ballcock assemblies:

Step 1: Turn off the tank’s water supply shutoff valve, then flush the toilet to drain the tank. Sponge up any remaining water in the tank before proceeding.

Step 2: Remove the old ballcock assembly following the procedure outlined above. Slip the parts over the water inlet pipe under the tank in this order: coupling nut, friction washer, cone washer, and retaining or mounting nut.

To replace a toilet’s fill valve, follow these steps. First, turn off the water supply to the toilet. Next, flush the toilet to drain the water. Then, disconnect the water supply line from the bottom of the tank. Remove the old fill valve by unscrewing the retaining or mounting nut under the tank and lifting the valve out of the tank. Install the new unit inside the tank, making sure the gasket fits into the hole and tightening the retaining or mounting nut under the tank onto the threaded shank. Attach one end of the refill tube to the tank’s overflow pipe and place the other end on the stem of the replacement unit. Finally, open the water supply valve to fill the tank and adjust the water level by using the knob on the new valve unit.

How to Address Common Toilet Problems

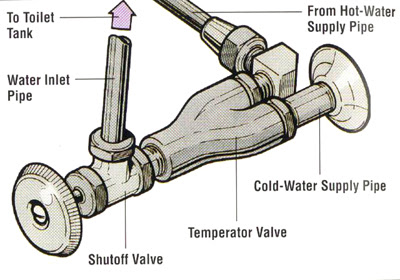

If your toilet doesn’t have enough water to clean the bowl, first check the water level in the tank. If the water level is too low, bend the float arm up slightly to allow more water to enter the tank. If the water level is correct but the bowl isn’t being cleaned properly, the problem may be the tank ball on the flush valve seat at the bottom of the tank. Adjust the guide to prevent the ball from dropping too soon. If the small ports around the underside of the toilet bowl’s rim are clogged, use a mirror and a wire coat hanger to remove debris. To prevent toilet tank sweating, consider using jackets or drip pans designed for this purpose, or install a temperator valve to regulate the temperature inside the tank and reduce condensation.

To prevent toilet tank sweating, a temperator valve can be installed that requires both hot and cold water supply connections.

Installing a temperator valve can be inconvenient if a hot water line is not easily accessible near the toilet. Additionally, the valve does not prevent water inside the tank from cooling between flushes, which can still cause condensation even with the valve. A leak in the toilet may be caused by loose connections or defective washers on the spud pipe or where the water inlet pipe and ballcock assembly attach to the tank. In this case, replace any worn gaskets or washers and tighten the nuts before testing with bluing in the water.

If water is seeping from under the toilet bowl, the wax ring seal joining the bowl to the drain outlet may be defective. To fix this, the bowl must be removed and a new gasket installed. If the leak is caused by a crack in the tank or bowl, the entire toilet must be replaced.

Replacing a Toilet

Removing and replacing a toilet is not a simple task, but it can be done if necessary. If the toilet cannot be unclogged using other methods, or if there is a crack or leak, the toilet will need to be removed and replaced. However, local plumbing codes may require a licensed plumber to perform the job, so it is important to check beforehand. To replace a toilet:

Step 1: Determine the rough-in distance, which is the distance from the wall behind the bowl to the center of the toilet floor drain. Measure from the wall to the center of either of the two hold-down bolts, or to the center of the rear bolt if there are two on each side.

Step 2: Choose a replacement toilet unit that will fit properly in the bathroom based on the rough-in distance. A more modern fixture can be installed, but it must fit in the space between the drainpipe and the wall. A smaller unit can be installed, but a larger toilet cannot be placed in a space previously occupied by a smaller fixture.

Step 3: Turn off the water supply to the toilet tank and remove all water from the tank and bowl. Use the flush handle to remove most water from the tank, then soak up any remaining water with a sponge. Remove any water in the bowl with a small container and dry the bowl completely with a sponge.

Step 4: If the tank is connected to the wall, remove the hanger bolts inside the tank and the pair of bolts at the bottom of the tank that connect it to the bowl. Remove the tank and set it aside.

To replace a toilet, start by removing the caps covering the hold-down bolts at the base of the bowl. These caps can be made of ceramic and held on by plumbers’ join compound or threaded. After removing the caps, brush away the dried compound. Then, remove the hold-down nuts or bolts, which may be stubborn but can be loosened with penetrating oil. Save the washers and bolts if you plan to reinstall the bowl. Once the hold-down nuts or bolts are out, plug the drain opening to prevent sewer gas from backing up while you work. Then, spread out an old piece of carpeting and gently rock the bowl back and forth to loosen it before lifting it straight up and setting it on the carpet. Inspect the uncovered drain and clear it if necessary before proceeding with the replacement of the toilet.

To install a new toilet or reinstall the old one, scrape away all the old putty or other sealing material from both the bottom of the bowl and the floor flange. Inspect the floor where the toilet was and rebuild it if it has rotted. Inspect the flange and bolts and replace any faulty parts. Install a new sealer ring on the water outlet opening on the bottom of the new bowl and apply a uniform layer of toilet-bowl setting compound around the edge of the bowl at the base.

To install a toilet, start by removing the plug from the drain or soil pipe. Turn the bowl upright and place it over the flange, guiding the bolts into place. Press down firmly and give the bowl a slight twist to ensure the wax ring is properly seated against the flange. Use a level to check if the bowl is level and adjust as needed, being careful not to disturb the seal of the wax ring.

Next, hand-tighten the nuts to hold the bowl to the floor, but do not over-tighten as this may cause the fixture to crack. Coat the nuts and bolts with toilet bowl setting compound and reinstall the caps.

If the tank and bowl are separate fixtures, attach the tank by rebolting a wall-mounted tank or reinstalling the bolts and washers that connect a bowl-supported tank. Replace any damaged parts. If the tank and bowl are connected with a spud pipe, apply pipe joint compound to the threads of the spud slip nuts and tighten them in place.

Finally, reconnect the water supply inlet pipe to the tank, ensure the ballcock assembly is properly attached, and turn the water back on.

For more information on toilets and other appliances, check out these related HowStuffWorks articles.

FAQ

1. What are the most common problems with toilets that require repair?

The most common problems with toilets that require repair are clogs, leaks, running water, and flushing issues. Clogs can be caused by a variety of things, including excessive toilet paper or foreign objects being flushed down the toilet. Leaks can occur in the tank, bowl, or pipes and can lead to water damage if not addressed promptly. Running water can be caused by a worn out flapper valve or a faulty fill valve. Flushing issues can be caused by a variety of reasons, including a faulty flush valve or a broken chain.

2. What tools are needed to repair a toilet?

The tools needed to repair a toilet include a plunger, adjustable wrench, screwdriver, toilet auger, and replacement parts such as a flapper valve or fill valve. A plunger is useful for dislodging clogs, while an adjustable wrench and screwdriver can be used to tighten loose bolts and nuts. A toilet auger can be used to remove stubborn clogs that a plunger cannot handle. Replacement parts such as a flapper valve or fill valve can be purchased at a hardware store.

3. How do you fix a running toilet?

To fix a running toilet, first, check the flapper valve to see if it is worn out or not sealing properly. If the flapper valve is the problem, replace it with a new one. If the flapper valve is not the issue, check the fill valve to see if it is faulty or needs adjusting. If the fill valve is the problem, adjust it or replace it with a new one. If neither the flapper valve nor the fill valve is the issue, check the overflow tube to see if it needs adjustment or replacement.

4. How do you fix a clogged toilet?

To fix a clogged toilet, first, try using a plunger to dislodge the clog. If the plunger does not work, try using a toilet auger to remove the clog. If the toilet auger does not work, remove the toilet from the floor and use a plumbing snake to remove the clog. Be careful not to scratch the porcelain when removing the toilet.

5. How do you fix a leaking toilet?

To fix a leaking toilet, first, determine where the leak is coming from. If the leak is coming from the tank, check the bolts and nuts holding the tank to the bowl to see if they need tightening. If the leak is coming from the bowl, check the wax ring to see if it is worn out or not sealing properly. If the wax ring is the issue, replace it with a new one. If the leak is coming from the pipes, check the connections to see if they need tightening or replacement.

6. When should you call a professional to repair your toilet?

You should call a professional to repair your toilet if you are not confident in your ability to make the repair, if the problem is severe or dangerous, or if you do not have the necessary tools or replacement parts. A professional plumber can diagnose and repair the problem quickly and efficiently, saving you time and money in the long run.

Brody is a skilled craftsman and gardening expert. From renovating living spaces to cultivating lush gardens, Brody’s knowledge and passion shine through, inspiring readers to embark on their own home improvement and gardening journeys with confidence.

Leave a Reply