Home Improvement

If your walls are not in perfect shape, there are many options available for covering them besides paint and wallpaper. This article discusses some creative ideas for wall treatments, including stucco, fabric, wood paneling, brick, or cork or mirror tiles. It also covers the installation of a wall safe. You can learn how to cover your walls with these options and avoid the need for extensive repairs and preparation required for traditional paint and paper.

We’ll begin by teaching you how to stucco a wall in the next section.

For more information on do-it-yourself home improvement projects, try the following links:

- If your floors need work, refer to our article on How to Repair Floors.

- Learn how to create your own walls with our article on How to Drywall.

- For instructions and tips on doing a good paint job, see our article on Painting Walls.

How to Stucco a Wall

Using a stiff brush or metal comb, create the desired texture with stucco.

If you have road-map walls and ceilings that need to be disguised, stucco paint is the solution. It can hide cracks and give the room a new look.

Tools:

- Bucket and sponge

- Putty knife or paint scraper

- Paint roller with loop-textured roller cover

- Trowel

- Stiff brush

- Metal comb

- Sponge, or sturdy cord for texturing

- Utility knife

- 3-inch paint roller

- Stepladder

Materials:

- Plastic dropcloths

- Masking tape

- Strong household detergent

- Spackling compound

- Textured or stucco paint

- Piece of scrap plywood or hardboard

- Liquid detergent

Time:

About 4 hours for a small room, plus additional preparation time as necessary

Preparing to Paint

Choose textured or stucco paint based on the condition of the walls and ceiling. Lightly textured paints are suitable for minor flaws, while heavy stucco paints can cover really bad walls. Read the paint label carefully and purchase enough paint for your needs. Stucco paint typically covers about 25 square feet per gallon can.

Before starting the project, prepare the surfaces to be stuccoed. If you’re stuccoing clean walls, leave the furniture in the room. If you’re stuccoing the ceiling or the surfaces require preparation, remove the furniture and other items. Protect the floor and furniture with plastic dropcloths and masking tape.

To prepare the room for stucco, clean the surfaces with a strong household detergent and hot water. Fill small cracks with paint and large cracks with spackling compound. Apply firm pressure and smooth with a putty knife. If the spackling compound shrinks or cracks, apply more and let it dry completely. Spread lightly textured paint with a roller or thick stucco paint with a special loop-textured roller cover or a trowel. Experiment with the paint on a scrap piece until you know how to get the desired effect. Apply paint to the surfaces and texture as you go. Let the paint dry according to the manufacturer’s instructions. Fabric is a suitable wall covering for any reasonably smooth surface.

Equipment:

- Step ladder

- Measuring tape

- Pencil

- Chalked plumb bob

- Long table

- Sharp scissors

- Staple gun

- Hammer

Supplies:

- Fabric

- Paper

- Straight pins

- Heavy-duty staples

- Household glue

- Lightweight stiff cardboard

- Cloth ribbon, braid, or narrow molding strips

- Small finishing nails or brads

Time: approximately 1 day

Selecting and Purchasing the Fabric

Choose fabric that is as wide as possible. Determine the number of strips needed to cover the walls and calculate the yardage accordingly. If the fabric has a repeating pattern, it must be matched on adjacent panels, like wallpaper. Add at least 2 yards to your total. If you plan to edge the wall with ribbon at the floor and ceiling, calculate the footage and add at least 2 yards. Purchase the ribbon and fabric together.

Measuring and Cutting the Fabric

Begin in the least noticeable corner of the room, such as behind the door. Measure along the ceiling from the corner a distance equal to the width of the fabric, minus about 1/4 inch. Set the plumb bob at this point and snap a chalk line to mark the edge for the first panel of fabric. Measure the height of the room from floor to ceiling.

Unroll the fabric on a long table with the right side face up. Cut the first panel of fabric as long as the height of the room, plus 2 inches. Unroll and cut the remaining fabric to be used around the room, being careful to match it to the pattern in the first panel.

To determine the exact length of each panel, measure the height of the wall where the panel will be placed and add 2 inches. Measure above and below windows and doors and cut the fabric accordingly, matching the patterns on both short strips. Pin a numbered tag to each panel as you work to keep the panels in order around the room.

Installing the First Panel of Fabric

Hold the first panel of fabric up against the wall at the marked corner. Turn the top end of the panel under 1 inch, holding it in place at both sides with your fingers. Stretch the fabric smoothly along the top edge of the wall and adjust it so that the outside edge of the panel lines up with the chalk line on the wall.

Staple the turned-under top of the fabric to the wall while holding it carefully to keep it lined up with the chalk line. Space the staples about 1 inch apart, as close to the ceiling and as even as possible. If the fabric is very heavy or sags badly, apply household glue sparingly along the turned-under end and press it into place until the glue sets.

Working from the top of the wall down, staple the corner side of the fabric to the wall, about 1/4 inch from the edge. Space the staples evenly, about 1 inch apart, and keep them straight up and down. Smooth the fabric carefully as you work to keep it lined up with the chalk line. Repeat to staple the other side of the fabric, setting staples 1/4 inch from the edge. Fold the excess fabric under at the bottom of the panel and staple it smoothly along the baseboard.

Adding More Fabric Panels

Prior to adding more fabric panels, cut sheets of lightweight cardboard into 1/2-inch strips. Make sure you have enough cardboard to create a solid strip from floor to ceiling at each seam. Cut the strips uniformly to ensure they are not visible under the completed fabric paneling.

Hold the second length of fabric against the first panel, face to face, with the wrong side of the fabric out. Leave 1 inch of extra fabric at the top of the panel and carefully line up the edges of the panels. Place a few staples through the first and second panels, about 1/2 inch in from the edges. These staples are temporary and not meant to be the final seam.

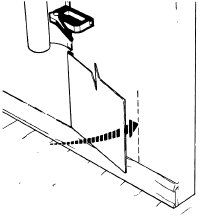

Staple the cardboard strips to hold the panel’s edge and then pull the fabric over onto the wall.

Staple 1/2-inch cardboard strips over the matched edges of the panels and attach them evenly to form a smooth, level edge with no gaps or overlaps. Once the cardboard seam is secure, pull the second length of fabric back over the cardboard strips to form a blind seam. Stretch the fabric smoothly out from the joint and staple it into place on the wall, working from the center of the panel up and down. Turn the excess fabric under and staple the panel neatly at the ceiling and baseboard. Use glue if necessary to keep the fabric from sagging.

Repeat the cardboard-strip technique to apply each new panel of fabric. Cut the fabric around windows and doors with about 1 inch excess on all sides of the obstruction. Turn the excess fabric under and crease it into place with your fingers, smoothing it as you go. Use staples only at the stress points and attach the fabric with glue if possible.

Finishing the Final Panel

When the last panel is in place, turn the edge of the first panel under the edge of the last and crease the seam with your fingers. Glue the folded fabric down, holding it in place until the glue sets. Do not use staples on the final seam.

Covering the Staples at the Top and Bottom

To cover the staples in the fabric along the ceiling and the baseboard, glue a long piece of cloth ribbon or braid over the edge of the fabric. Turn the ends under carefully so they do not unravel. Alternatively, tack narrow molding strips over the stapled fabric along the baseboard.

Fabric paneling is a great option for walls that are too damaged to hold a new treatment. For more information on do-it-yourself home improvement projects, try the following links:

In need of repairing your floors or creating your own walls? Look no further than our informative articles on How to Repair Floors and How to Drywall. And for tips on painting walls like a pro, check out our article on Painting Walls.

But if you’re looking to panel a room with plywood or hardboard sheets, we’ve got you covered with our step-by-step guide. To start, nail a grid of furring strips to studs on uneven or cracked walls, and shim low spots solidly.

It’s important to note that you should not install paneling directly on an unfinished stud wall. Instead, provide a sound base with a framework of 1×2 or 1×3 furring strips. And don’t forget, you’ll need an assistant to handle the panels as they can be difficult to maneuver.

Before diving in, make sure you have all the necessary tools and materials including measuring tools, saws, safety goggles, and panel adhesive. And be sure to calculate how many panels you’ll need before purchasing.

Preparing for installation involves laying furring strips parallel on the floor and stacking the panels on top, allowing them to adjust to the room’s temperature and humidity. And with a little patience and attention to detail, you’ll have a beautifully paneled room in just 2 to 3 days.

Before paneling a room, it is important to ensure that the walls are smooth and level. Start by removing baseboards and molding from the walls. With an assistant, hold a long straight board horizontally against each wall surface and slide it up and down to identify high spots and depressions. Use plastic dropcloths to protect the floor. Fill low spots in the walls with spackling compound and sand high spots with coarse-grit sandpaper.

If the wall is very uneven or badly cracked, you must nail 1×2 or 1×3 furring strips up to give the paneling a solid base. Use a magnetic stud finder to locate the studs across each wall and mark these points. Snap a chalked plumb line from each marked point to mark the nailing lines for the furring strips. Nail furring strips horizontally across each wall with 8-penny common nails, nailing into the marked studs. Wedge shims behind the strips at any low spots and drive a nail through both the furring strip and shim into the wall. Cut vertical pieces to fit between the horizontals and set vertical strips from floor to ceiling in each corner, nailing them along the chalked stud lines. Nail vertical furring strips the same way, floor to ceiling, at wall studs at every point where two wall panels will meet.

For masonry walls, attach furring strips horizontally with steel masonry nails: one strip at the floor, one at the ceiling, and others at 16-inch intervals up the wall. Set vertical strips at the corners and at panel joints, shimming them out where necessary. Paint the joint-line strips and let dry. Cover the walls with heavy polyethylene sheet plastic from floor to ceiling to protect the paneling from moisture. Staple the plastic carefully and evenly into place over the furring strips, making sure it’s drawn smooth over the walls.

Before paneling, remove switch and outlet cover plates and pull the boxes out from the wall to match the thickness of the paneling, being careful not to disturb the wiring.

To cut the paneling, measure the distance from floor to ceiling at several points along the first 4-foot span. The panels must be nailed into place with a 1/4-inch gap at both floor and ceiling to allow for expansion of the wood. Mark the top of the panel to be trimmed and turn the panel face down over two sawhorses, with two long 2 × 4’s under it to keep it from bending. Cut it to measure with a fine-toothed saber saw or circular saw, wearing safety goggles while making the cut.

Creating Perfect Corners

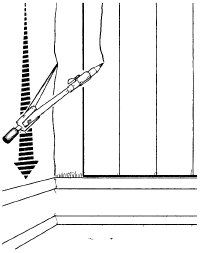

To achieve a seamless fit in the corner, the first panel must be scribed. Begin by positioning the panel in the corner and placing shims underneath to elevate it by 1/4 inch. Check that it is perfectly vertical using a level.

There will likely be an uneven gap between the panel edge and the corner. With the help of an assistant holding the panel in place, use a scribing compass to trace a line along the corner from the top of the panel to the bottom. Be sure to press down firmly to create a fine pencil line. Cut the panel carefully along this line using either a saber saw or a coping saw.

How to Install Paneling

There are several options for installing paneling, including nails, adhesive, or a combination of the two. It is important to follow the manufacturer’s recommendations. Heavy plywood panels should be nailed, while even lightweight panels should be nailed at the floor and ceiling. The nails will be concealed by the moldings used at the top and bottom of the wall.

Nailing Method: Begin by setting the first panel carefully into place in the corner, with the edge trimmed as necessary. Place shims underneath to maintain the 1/4-inch gap at the floor and ensure that it is plumb. Starting at the furring strip or stud line at the center of the corner edge, drive a row of nails across the center of the panel at 12-inch intervals. Sink the nail heads without damaging the paneling using a nail set.

Move up to the next horizontal furring strip and repeat, working from the center of the panel up and out. Continue nailing up to the ceiling and down to the floor, spacing nails 12 inches apart along every horizontal furring strip or on each marked stud line of a wall being covered directly. Once the entire panel has been nailed down, drive nails every 6 inches around the edges and remove the shims from the bottom.

Repeat the process around the room, trimming each panel as needed and scribing each corner panel. When working around doors, windows, or outlets, use the protective paper sheets that come between the panels. Tape the paper sheet firmly against the wall where the panel will go, trace the outline of the obstruction, and cut out the traced area. Transfer the cutouts onto the panel and use a saber saw or circular saw for larger openings and a coping saw or keyhole saw for smaller holes.

How to Install Brick Panels with Adhesive

To install brick panels with adhesive, begin by using the brand recommended by the panel manufacturer. Apply the adhesive with a caulking gun and start in the corner with the scribed and trimmed first panel. Run a solid bead of adhesive over all furring strips the panel will cover. If paneling over a solid wall, apply adhesive in a grid pattern. Set the panel into place in the corner, resting on shims to maintain the 1/4-inch gap at the floor. Once in position, drive a row of nails at 12-inch intervals across the top of the panel.

It is important to follow the instructions for the panel adhesive. Depending on the adhesive you’re using, you may have to pull the panel away from the wall until the adhesive is tacky. If this is the case, pull the bottom of the panel out from the wall and prop it in place with a piece of scrap wood for the time specified by the manufacturer. Then remove the prop and press the panel flat against the wall.

Once the panel is flat against the wall, set it permanently by pounding it firmly into place with a hammer and padded wood block. Drive nails at 6-inch intervals all along the floor and ceiling edges of the panel, and remove the shims under the bottom edge.

Continue around the room, measuring and trimming as you go. Finish installing each panel before you move on to the next one.

Completing the Paneling

After installing the brick panels, fill all nail holes with wood putty. Install prefinished ceiling and baseboard molding, mitering corners with a miter box and a fine-toothed backsaw, and nail the molding into place.

If you want to bring the look of brick to your home, it is easy to cover a wall with brick. Use bricks cast thin for interior use and set them into place with adhesive.

For more information on do-it-yourself home improvement projects, check out the links below:

- How to Repair Floors

- How to Drywall

- Painting Walls: Tips and Techniques

Required Tools:

- Measuring tool

- Bucket and sponge

- Putty knife or paint scraper

- Sanding block

- Wall-cleaning sponge, or large paintbrush and broad-bladed scraper

- 3/8-inch dowel rod

- Line level

- Chalk

- Safety goggles

- Cold chisel and hammer

- Tile nippers

- Coarse file

- Notched trowel

Materials Required:

- Graph paper

- Strong household detergent

- Plastic dropcloths

- Spackling compound and fine-grit sandpaper, or wallpaper remover and wall sizing

- Thin glue-on interior bricks

- Adhesive and adhesive solvent as recommended by the brick manufacturer

- Clean rags

Time Required: Several hours for a small wall, after wall surface is prepared

How to Buy the Bricks

Prior to purchasing the bricks, draw a brick layout on a piece of graph paper and count the number of bricks required for corners. Interior face brick is sold in packages that cover 5 square feet. To determine the number of required packages, calculate the square footage to be covered and divide it by 5. An extra package of brick and a few extra corner bricks should be purchased to account for wastage. Consult the dealer for the recommended amount of adhesive and adhesive solvent to purchase.

Wall Preparation

The wall must be prepared before applying the bricks. If the wall is very dirty or greasy, clean it with a strong household detergent. Use plastic dropcloths to protect the floor. Fill cracks and holes with spackling compound and scrape painted surfaces. Allow the spackling compound to dry and sand it smooth with fine-grit sandpaper. Use a wall-cleaning sponge to remove all dust.

If the wall is wallpapered, remove any loose wallpaper. Apply wallpaper remover with a large paintbrush, leave as directed by the manufacturer and carefully scrape off all old paper. Rinse the wall with clean water to remove all paste and let it dry. Apply wall sizing to seal the wall as per manufacturer’s instructions. Let it dry completely.

Brick Laying and Cutting

Use a 3/8-inch dowel rod to measure brick joints as you work. Use a line level to mark the bottom edge of the bricks along the floor with chalk. Small gaps below the line can be filled in with brick adhesive. Set out two rows of bricks on the floor, 3/8 inch apart, to understand how to place them on the wall. Arrange the bricks in such a way that the bricks at the right end of each row will be the same size as those at the left end when they’re cut to fit.

Wear safety goggles while cutting the end bricks to the correct size. Use a cold chisel and hammer to score both sides of each brick. Then cover the brick with a rag and break it in two with a sharp hammer blow. Remove any pieces left along the broken edge with tile nippers. Smooth the broken edge, if necessary, with a coarse file.

How to Apply Bricks

After checking the layout and cutting the end bricks, spread a layer of adhesive evenly on the wall with a notched trowel. Start at one of the corners along the chalk line that indicates the bottom row of bricks. Cover only about 3 square feet of wall surface at a time. To set each brick, put adhesive on the back of the brick and press it firmly against the wall. Twist the brick slightly as you place it. Use a dowel rod to establish and maintain a 3/8-inch joint width between bricks.

Continue across and up the wall, placing one row of bricks at a time and keeping them spaced 3/8 inch apart. After finishing each row, check its straightness with a line level. Use special corner bricks if you need to turn a corner.

Once all the bricks are set, fill in any gaps at the edges of the wall with adhesive. Finally, use the dowel rod to smooth joints where necessary and clean adhesive from the brick face with a rag soaked in adhesive solvent. Discard solvent-soaked rags and dropcloths.

If you want to give your house a unique look, you can try using mirror or cork tiles. We will discuss these methods on the following page.

For further information about DIY home renovation projects, check out the following links:

- If your floors need repairs, you don’t have to hire expensive specialists. Read our article on How to Repair Floors.

- Learn how to construct your own walls with our article on How to Drywall.

- For instructions and tips on painting walls well, read our article on Painting Walls.

How to Install Mirror or Cork Wall Tiles

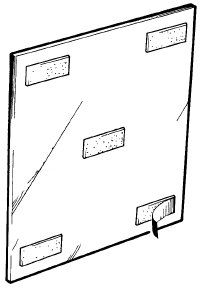

Mount each tile with tabs of wall-mount tape, at the corners and in the center.

Cork tiles provide warmth and serve as an instant bulletin board, while mirror tiles make a small room appear larger and are much less expensive than a plate-glass mirror. Both types of tile are simple to install.

Tools:

- Measuring rule

- Pencil

- Level

- Chalk line

- Scissors

- Chalk

- Yardstick

- Sharp utility knife, heavy-duty scissors, or glass cutter

- Safety goggles

- Work gloves

Materials:

- Graph paper

- 3/22-inch-thick, distortion-free glass mirror tiles or cork squares

- Heavy-duty double-stick wall-mount tape

- Newspaper

Time: Approximately 2 hours for an 8×10-foot area

Planning the Wall and Buying Materials

Purchase mirror or cork tiles pre-cut in 1-foot squares. Before buying the tiles, measure the wall or door that needs to be covered and draw it on graph paper. Plan the pattern you want to use – a simple block pattern is the easiest, but you can also set the tiles in a diamond or other pattern. If you are only tiling part of a wall, you won’t need to cut the tiles. However, if you’re tiling the entire wall, arrange the tiles in such a way that you have to cut the fewest possible tiles at the wall’s edges.

Count the number of tiles you need and allow for several extra tiles for wastage if you need to cut tiles. If the tiles do not come with mounting tape, buy heavy-duty double-stick wall-mount tape to use.

Preparing the Wall for Tile Installation

Prior to installing tiles on the wall, ensure that the wall is clean and smooth. Remove any loose paint or wallpaper and smoothen the wall surface if required.

Begin tiling from a bottom corner of the wall or from the floor on one side of the area that needs to be covered. Snap a chalk line down the wall at the corner and verify its plumb by using a level; adjust the line as necessary. If the corner is not plumb, it is better to stop the tiles short of the corner rather than cutting them to fit.

Installing the Tiles

To install the first row of tiles, start with the bottom or corner tile. If the tiles have mounting tape on the reverse side, peel off the backing paper as you place each tile. If the tiles do not include mounting tape, cut five pieces of heavy-duty double-stick wall-mount tape each measuring 11/2 inches. Apply a piece of tape to each corner of the tile, parallel with the tile edge, and set the last piece in the middle of the tile. Align the side of the tile on the chalk line and press it firmly but gently into place. Work up the chalk line to set each tile in the first row; work vertically and butt the bottom of each tile against the top of the last one. Place tiles the same way all across the area to be covered, butting the edge of each tile against the tile edge of the last row.

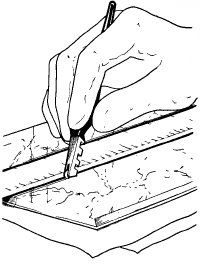

Score mirror tiles with a glass cutter; snap back along the score to complete the break.

Cutting Tiles

To cut cork tiles, mark the required width with chalk and cut using a sharp utility knife. Use a yardstick as a straightedge; if the tiles are thin, use a heavy-duty scissors. To cut mirror tiles, mark the required width and spread newspaper to protect your work surface. Set the marked tiles face up on the paper and score each tile at the marked point with a glass cutter while wearing safety goggles. Hold the cutter vertically and cut along the yardstick as a straightedge. Wearing work gloves, turn the scored tile over and snap it sharply backward to break it at the scored line.

Finishing the Wall

After all the tiles have been cut and set, review the tiles to ensure they are securely in place. Press each tile gently but firmly at the corners and in the middle to bond the wall-mount tape completely to the wall and to the tile surfaces.

On our final page, you will learn how to install a wall safe.

For more information on do-it-yourself home improvement projects, try the following links:

- If your floors need work, you won’t need to hire expensive specialists with our article on How to Repair Floors.

- Learn how to create your own walls with our article on How to Drywall.

- For instructions and tips on doing a good paint job, see our article on Painting Walls.

How to Build a Wall Safe

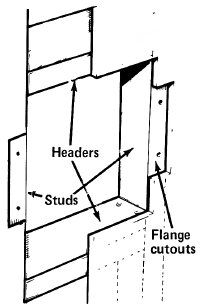

Cut an opening between the studs; remove drywall for the safe’s flanges. Add double headers at top and bottom.

Installing a small wall safe in your home is a convenient way to safeguard valuables, and it is effortless to install.

Equipment:

- Pencil

- Keyhole saw or saber saw

- Measuring rule

- Carpenters’ square

- Hammer

- Caulking gun

- Magnetic stud finder

- Brace and bits

- Putty knife

- Butt chisel

- Adjustable wrench

Materials:

- Wall safe

- 2×4’s

- 16-penny common nails

- 1/2×2-inch lag screws

- Spackling compound

- Construction adhesive

- Scrap drywall

- Sandpaper

- Finishing materials

Time: Approximately 4 hours

Purchasing a Safe

Wall safes are an effective method of protecting valuables from both burglars and fires. Many home safes are built to withstand temperatures of up to 2000 degrees Fahrenheit for 1 hour. Safes come in various styles and types, so it is advisable to purchase the safe that suits your needs from a lock and safe company. Listings can be found in the telephone advertising pages.

Where to Install a Safe

The most suitable location for a safe is in a wall that separates a closet area. The depth of the safe can vary from 6 to 10 inches or more, and since it is installed between studs, back space is necessary to accommodate this depth. If wall space is limited, the safe can be installed in a floor over a crawl space and covered with a trap door or throw rug. Select a location out of the room’s traffic pattern, such as under a shelf in the pantry or in a kitchen base cabinet.

To install the safe in a wall, choose a site and locate two parallel wall studs using a magnetic stud finder; most wall studs are 16 inches apart. Draw a vertical line identifying each wall stud, as the safe will rest between these studs. Measure the length of the safe, and draw lines between the stud lines to mark the top, bottom, and sides of the safe.

Cutting into the Wall

Using a brace and a 1/2-inch bit, drill holes in the wall at opposite corners of the outline, inside the lines and just touching them. Ensure the holes are inside the stud; once you’ve exposed the stud, it can serve as your vertical sawing guide. Saw out the hole for the safe with a keyhole saw or a saber saw. Trim any miscutting with a butt chisel. Remove the drywall over the studs where the flanges of the safe will be connected to the studs.

If there’s a finished wall on the opposite side of the wall, remove the wall sheathing from the safe area on this side. Transfer the dimensions of the wall safe onto this opposite wall, drill starting holes, and cut along the lines as above; make sure the hole on the opposite side lines up perfectly with the original hole. Do not cut out drywall for the safe’s flanges.

Building the Headers

Measure and cut four 2 × 4’s for headers to fit between the studs. Make double headers by nailing two 2 × 4’s together with 16-penny common nails. Toenail these double headers to the wall studs, setting one just below and one just above where the safe will rest.

Installation of the Safe

To install the safe, screw it through the flanges into the studs. Place the safe in the hole and mark the position of the lag screws on the studs. Take out the safe and drill pilot holes at the marked screw points using a 1/8-inch bit. Once done, place the safe back and align it with the drilled holes. Ask your helper to hold it in position. Use an adjustable wrench to drive lag screws through the holes and into the studs. Tighten them firmly.

Once the safe is secured into the wall, cover the flanges and bolt heads with strips of scrap drywall and attach them with construction adhesive. If required, make small holes for the lag screw heads in the gypsum board. Fill all the joints of the patches with spackling compound and allow the wall to dry. Then sand the surface until it is smooth and finish the wall.

For more information on DIY home improvement projects, check out the following links:

- Need to fix your floors? Our article on How to Repair Floors can help you avoid expensive specialists.

- Wondering how to create your own walls? Our article on How to Drywall is here to guide you.

- To get tips and guidance on doing a good paint job for your walls, read our article on Painting Walls.

FAQ

1. What tools do I need to install wall treatments?

You will need various tools depending on the type of wall treatment you are installing. For most wall treatments, you will need a measuring tape, level, pencil, utility knife, paint roller, and paintbrush. For wallpaper, you will also need wallpaper paste, a smoothing brush, and a wallpaper scoring tool. For wainscoting, you will need a saw, nail gun, and wood putty. It’s important to read the installation instructions for your specific wall treatment to ensure you have all the necessary tools.

2. Do I need to prepare my walls before installing wall treatments?

Yes, it’s important to prepare your walls before installing any type of wall treatment. This includes cleaning the walls to remove any dirt and debris, filling in any holes or cracks with spackle or putty, and sanding the walls to create a smooth surface. If you are installing wallpaper, it’s important to prime the walls so the wallpaper paste adheres properly.

3. How do I measure my walls for wall treatments?

Start by measuring the height and width of each wall you plan to install a wall treatment on. Multiply the height and width measurements together to determine the square footage of each wall. Add up the square footage of all the walls to determine how much material you will need. It’s important to add 10-15% extra material to account for waste and mistakes.

4. Can I install wall treatments over existing wallpaper?

No, it’s not recommended to install wall treatments over existing wallpaper. The wallpaper may not adhere properly and could cause the new wall treatment to bubble or peel. It’s best to remove the existing wallpaper before installing a new wall treatment.

5. How do I remove existing wallpaper?

To remove existing wallpaper, start by scoring the wallpaper with a wallpaper scoring tool. This will create small perforations in the wallpaper and allow the wallpaper remover solution to penetrate the adhesive. Next, apply a wallpaper remover solution to the wallpaper and let it sit for 10-15 minutes. Use a scraper to gently remove the wallpaper, being careful not to damage the walls underneath. Once all the wallpaper has been removed, clean the walls with warm soapy water and let them dry completely before installing a new wall treatment.

6. How do I install wallpaper?

Start by measuring the height and width of the wall to determine how much wallpaper you will need. Cut the wallpaper into strips, leaving a few extra inches at the top and bottom to allow for trimming. Apply wallpaper paste to the back of the wallpaper with a paint roller or brush. Carefully position the wallpaper on the wall and use a smoothing brush to remove any air bubbles. Use a utility knife to trim the excess wallpaper at the top and bottom of the wall. Repeat this process for each strip of wallpaper, being careful to match the pattern at the seams.

7. How do I install wainscoting?

Start by measuring the height and width of the wall to determine how much wainscoting you will need. Cut the wainscoting to size using a saw. Attach the wainscoting to the wall using a nail gun, being careful to avoid any electrical or plumbing lines. Fill in any nail holes with wood putty and sand the wainscoting to create a smooth surface. Prime and paint the wainscoting to match the rest of the room.

8. Can I install wall treatments on textured walls?

Yes, you can install wall treatments on textured walls, but it may be more difficult to get a smooth finish. It’s best to choose a wall treatment that can be applied directly to the textured walls, such as textured wallpaper or paint. If you want to install a smooth wall treatment, you may need to sand the walls to create a smooth surface before installing the wall treatment.

9. How do I paint a room with wall treatments?

Start by painting the walls with a base coat of paint in the desired color. Let the paint dry completely before installing the wall treatment. Once the wall treatment is installed, touch up any areas that may have been damaged during installation. Use a paint roller and brush to apply a top coat of paint to the walls and wall treatment. Be sure to use a paint that is compatible with the wall treatment material to ensure a long-lasting finish.

10. How do I remove wall treatments?

To remove wall treatments, start by using a utility knife to score the surface of the wall treatment. This will allow any removal solution to penetrate the surface. Apply a removal solution to the wall treatment and let it sit for the recommended amount of time. Use a scraper to gently remove the wall treatment, being careful not to damage the walls underneath. Once all the wall treatment has been removed, clean the walls with warm soapy water and let them dry completely before installing a new wall treatment.

Brody is a skilled craftsman and gardening expert. From renovating living spaces to cultivating lush gardens, Brody’s knowledge and passion shine through, inspiring readers to embark on their own home improvement and gardening journeys with confidence.

Leave a Reply